Top Sales Environmentally Friendly Rotary Type Decoating Furnace for Aluminum Recycling Line

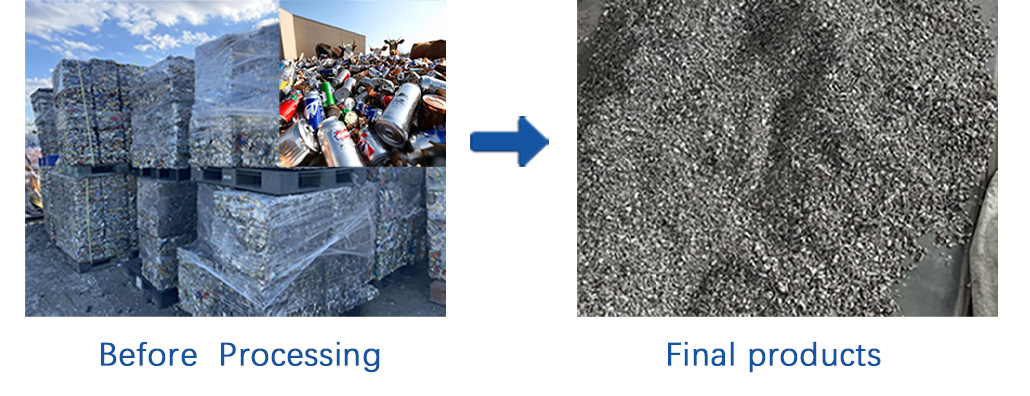

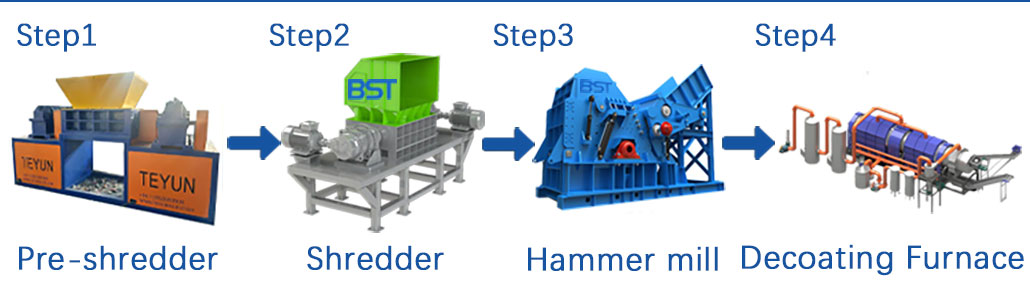

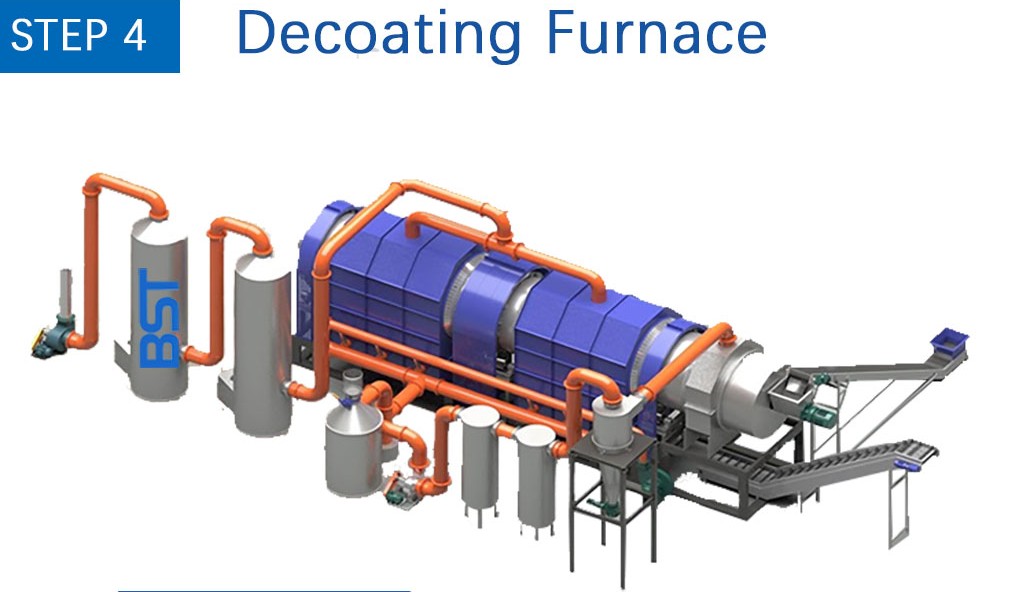

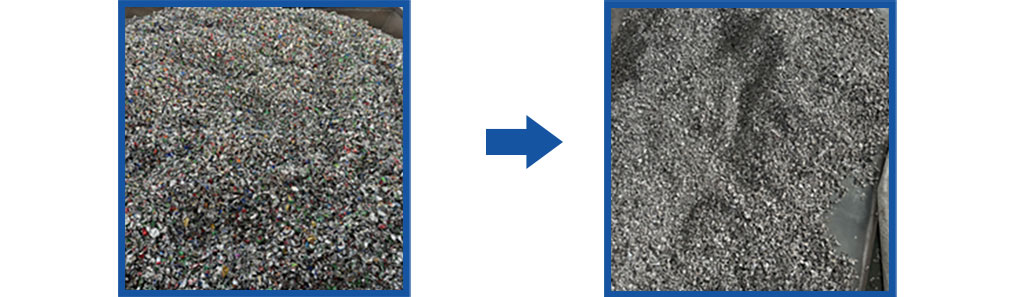

This decoating furnace easily strips paint from crushed beverage cans using rapid, controlled heat. As coatings crumble away, clean aluminum fragments emerge undamaged. The system runs trouble-free around the clock—clever controls automatically adjust temperature while sealed chambers protect metal quality. Filters and ducts capture every speck of residue, ensuring cleaner metal for smelting and full compliance with emissions rules.

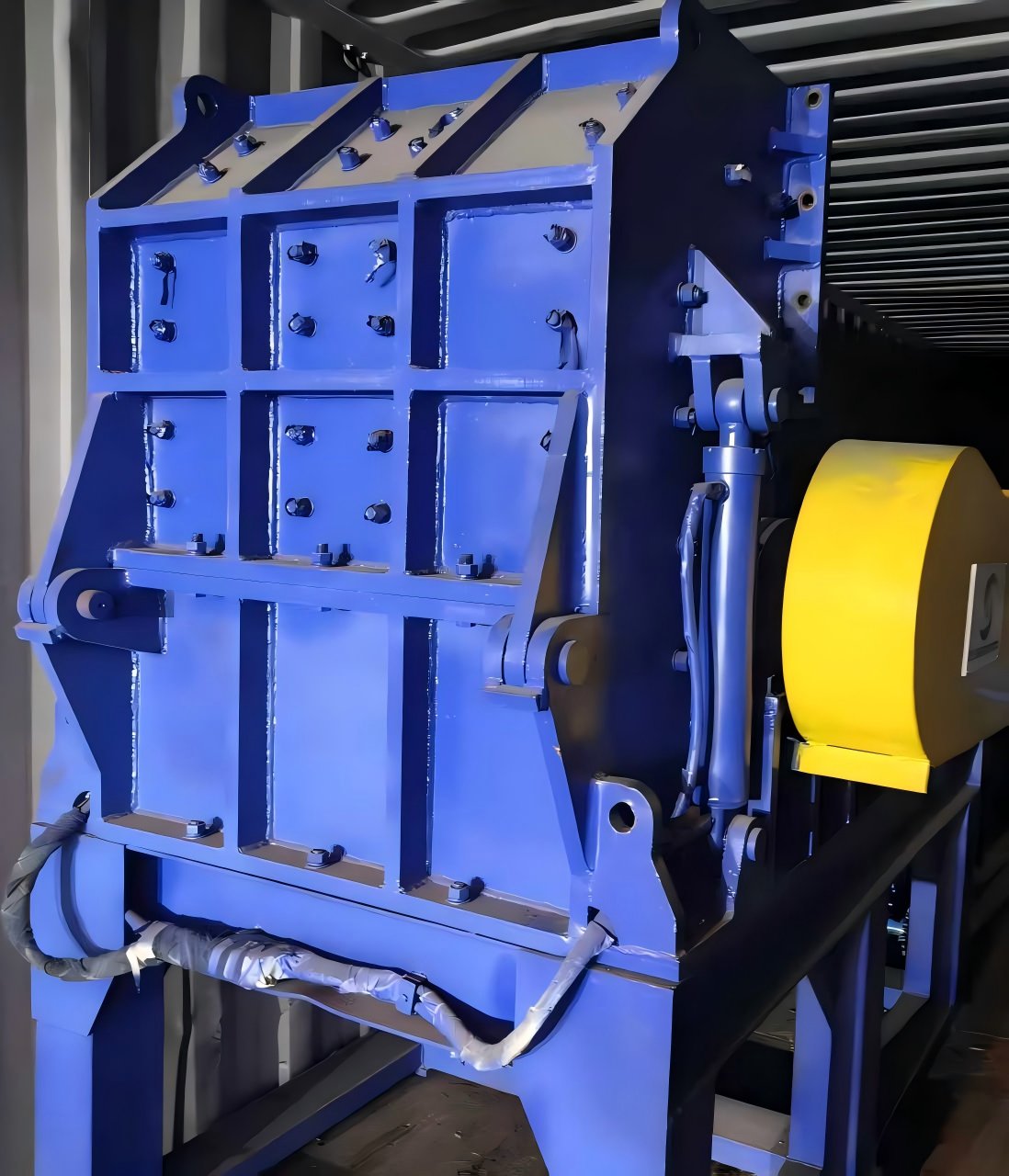

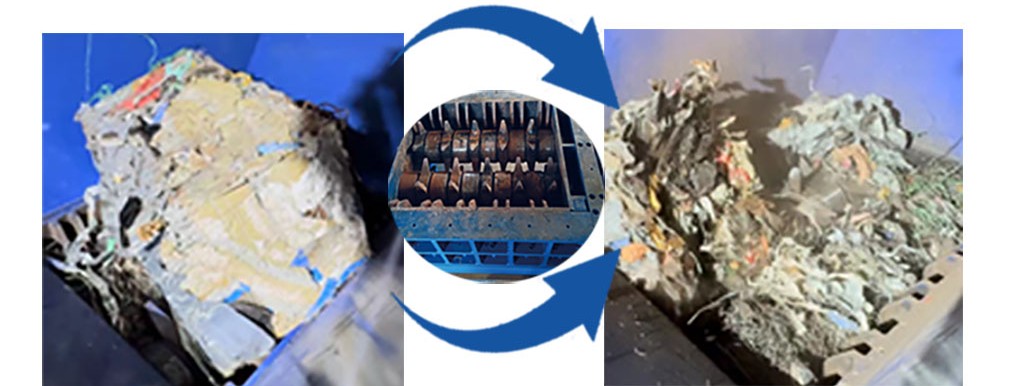

For the step one we use the Pre-shredder, to pre-deal with the bigger size metal scraps which are too big to put into the shredder and big size may broke the shredder. So the pre-shredder main function is to deal with the big size into the small size which suits for the shredder for next step.

--------------占位---------------

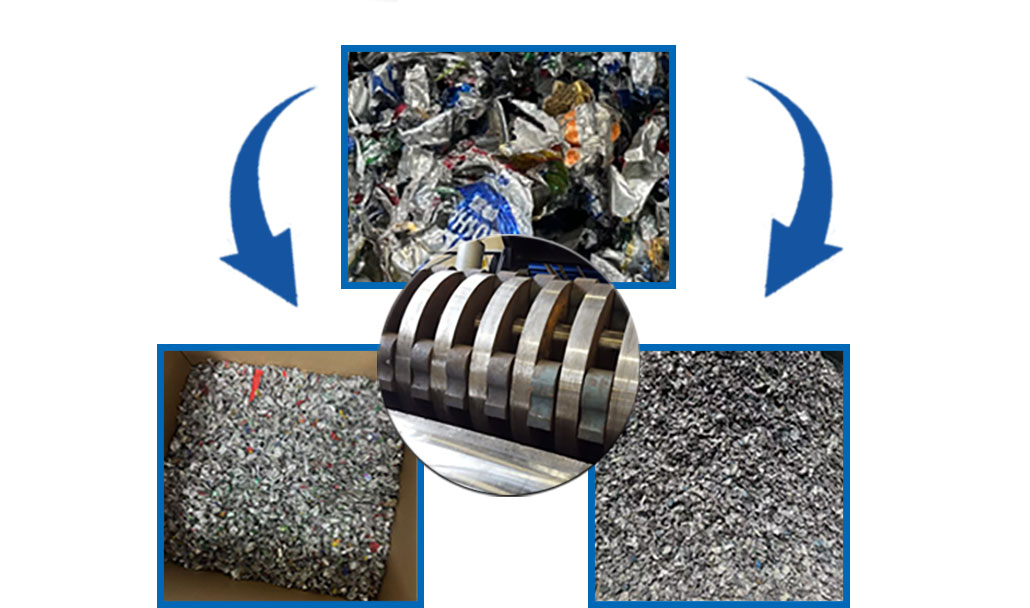

It can be frequently reversed, Alloy casting, long service life. H13 shredder blade

High quality burners Second generation dust removal equipment Integrated electrical box

| Model | Best Feeding Temperature | Decoating Time | Processing Capacity (kg/h) |

| TY-1500 | 540℃ | 20-30min | 800 |

| TY-1800 | 540℃ | 20-30min | 1200 |

| TY-2200 | 540℃ | 20-30min | 1500 |

English

English Français

Français Русский

Русский Español

Español Português

Português عربي

عربي 日语

日语