Why Continuous Decarbonizing Furnaces Are Replacing Chemical Paint Strippers

Oct 18, 2022

In metal recycling and refurbishment, removing paint and coatings from surfaces is a crucial step. For decades, chemical strippers were the default solution. Today, however, continuous decoating furnaces are rapidly becoming the preferred choice, offering a superior blend of efficiency, safety, and sustainability.

So, what makes this technology so much better? Here’s a straightforward look at its key advantages over traditional chemical methods.

1. Unmatched Efficiency and Continuous Operation

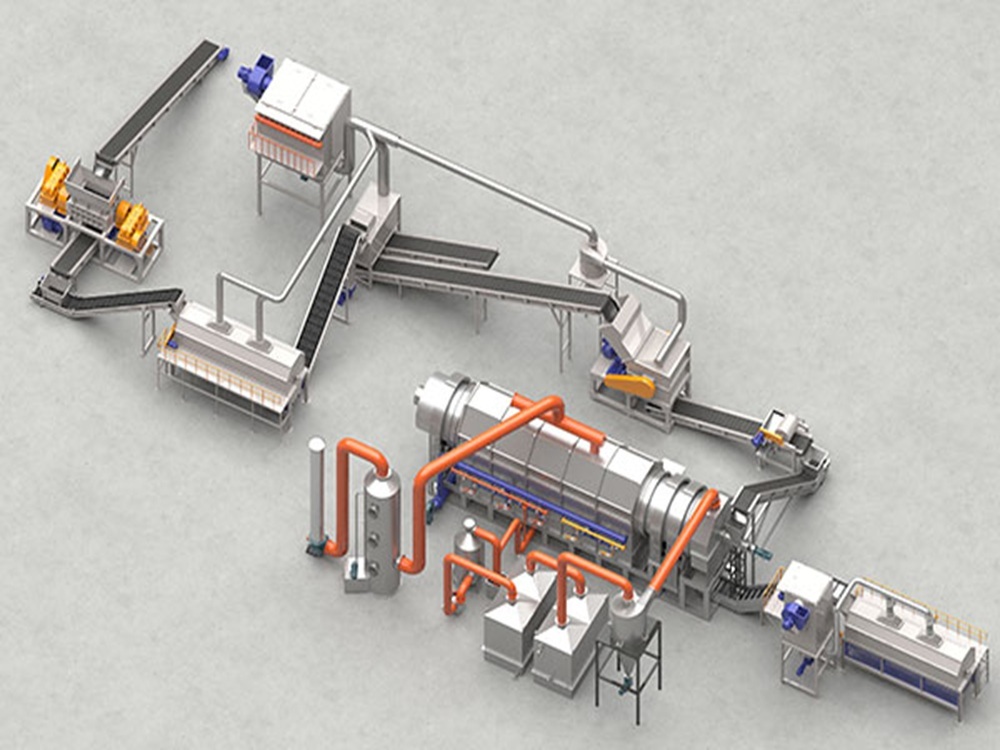

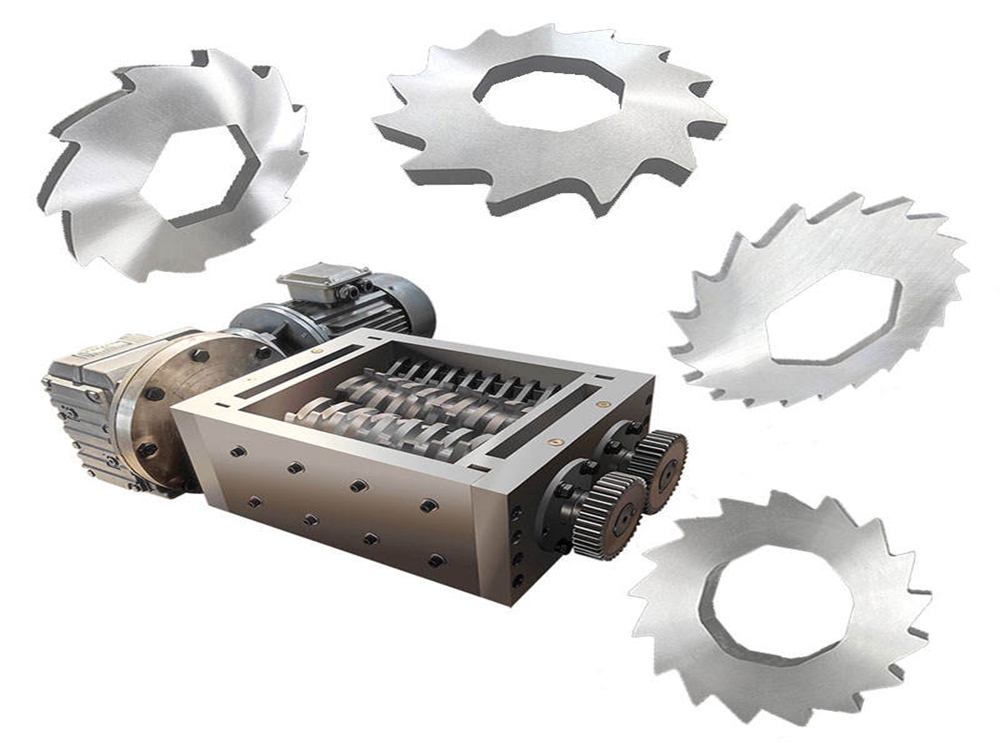

Imagine an assembly line for cleaning metal. That's essentially what a continuous decoating furnace is. Unlike batch processes, it operates non-stop, feeding metal parts through different zones for heating, processing, and cooling.

This continuous workflow translates to vastly higher throughput. Whether the items have thin or thick paint layers, the furnace parameters—like temperature and processing speed—can be easily adjusted to achieve a perfect, clean strip. This flexibility makes it ideal for handling a wide variety of metal parts efficiently, saving significant time and labor.

2. A Clear Win for Safety and the Environment

This is perhaps the most significant advantage. Chemical paint strippers often contain harsh, toxic substances that pose risks to worker health and the environment. Safe handling requires strict protective measures, and the disposal of used chemicals creates hazardous waste.

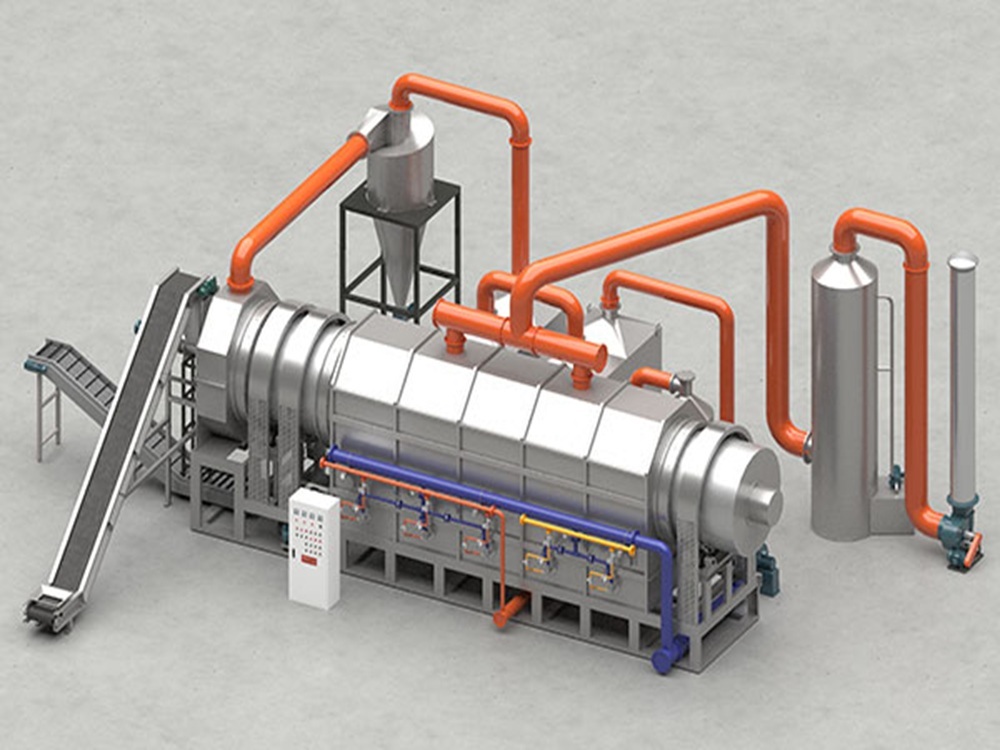

The decoating furnace eliminates this problem entirely. It uses high temperatures in a controlled, oxygen-free environment to break down paint into gas and a small amount of solid residue. It's a purely physical process—no toxic chemicals are needed. This means no dangerous fumes for workers, no risk of chemical spills, and no toxic wastewater to treat. It’s a much cleaner and safer solution for everyone.

3. Simple Operation and Easy Maintenance

Managing chemical strippers is complex. It requires careful monitoring, storage, and handling procedures to prevent accidents. In contrast, continuous decoating furnaces are designed for simplicity. Modern units are equipped with automated control systems that manage the entire process—temperature, conveyor speed, and atmosphere are all precisely controlled from a panel.

This automation reduces the potential for human error and minimizes the need for specialized operator intervention. Maintenance is also straightforward, typically involving regular inspections and basic servicing to ensure long-term, reliable performance.

4. Handles Almost Any Metal Part

Versatility is a major strength. These furnaces can be adapted to process metal parts of various shapes and sizes, from small components to large structural pieces. By fine-tuning the equipment settings, different materials and coating types can be effectively treated. This broad adaptability makes the technology useful across many industries, including automotive manufacturing, aerospace, metal recycling, and general metalworking.

5. Energy Efficient and Cost-Effective

While heating a furnace requires energy, modern continuous designs are built for efficiency. Advanced insulation and heat recovery systems capture and reuse heat within the furnace, significantly reducing energy consumption. Furthermore, the combustible gases produced during the paint removal process can often be captured and used to fuel the system, creating an energy-saving loop.

Over time, these efficiencies lead to lower operating costs compared to the recurring expense of purchasing and disposing of chemical strippers.

The shift from chemical paint strippers to continuous decoating furnaces represents a major step forward for industry. With their superior efficiency, enhanced safety profile, environmental benefits, and operational simplicity, these furnaces are not just an alternative—they are a clear upgrade. They align perfectly with the goals of modern, sustainable manufacturing, helping businesses work smarter, safer, and greener.

Read More